Analysis of impedance fault during wire harness machining

The processing technology of wire bundling processing plant mainly includes editing, crimping terminal, assembling wire sleeve, tape winding, wire tube, single pairing, processing technology and so on. The plastic art text documents include the blanking length of the cable, the disengagement length, the model, specification, model of the crimped terminal, the opening specification of the raw material covered by the pipeline, and the method and direction of the single pair production process. For possible wire harness production, also includes materials and: Electronic wire harness CAPP systems need to have the following mechanical kinetic energy. Product information input effect is good. Product information for electronic wiring harnesses includes terminal solid models (or suspension tin solutions), surface coverings, individual pairing, precise positioning associations, and more. In order to ensure the accuracy of product information input, the product information input module should be big data visualization, easy to check and change. Wire harness machining system test. Perform a comprehensive short-circuit test on the product information, check that all control circuits and connection points are off, check the start and end of the power supply, and check that the connection points of the circuit are correct. One click to generate process files and production process functions. According to the structural information of the new product, the appropriate process indicators can be selected, and the process data can be generated with one click, including the manufacturing process of the cable opening socket, the manufacturing process of the cable single distribution equipment, the manufacturing process of the pipeline opening wire tube, raw materials, working time calculation and production photos, which can facilitate the query of the product production process and export printing. Management method manufacturing process database system.

The function of the production process database management also includes the management of product structure information, process files and various process data required by the production process (raw materials, plastic art methods, basic parameters of plastic art cost, basic parameters of work calculation time, etc.). Since the impedance of the wiring harness factory is one of the basic parameters to describe the McRain, the impedance to identify the McRain is higher and the standard voltage is lower than that of the low-impedance microphone. However, most of the better microphones are low-impedance, and the transformer must be input in front of its amplifier to increase the power difference signal of the microphone signal. Low impedance microphones have many advantages, which is very meaningful for wire harness machining. Strong video stream impedance can also cause high-frequency damage when the microphone is connected to harness machining, while low video stream impedance can reduce this high-frequency damage and use relatively long harness machining.

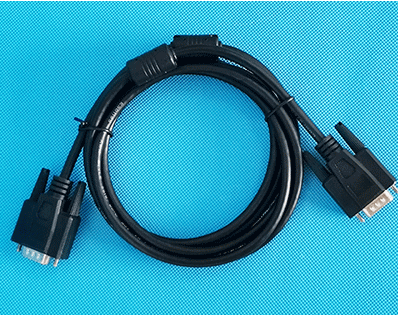

For the wiring harness processing plant, only the data cable on both sides of the wiring harness processing is transferred to the inspection expansion interface, and the inspection is completed according to the learning function or the writing of the test program. However, when testing complex equipment performance and network cabling, we must consider many factors. First, data cables come in many sizes and models. The same type of data cable has differences in head holes, seat pins, head pins and seats, and the total number of data cables (or number of fabrications) is also different. How to solve the connection between the tester and these data cables and the need for more efficient testing is a key issue to be solved this time. Secondly, the test module of the tester network server has a total of 8 data cables, and the number of functional tests reaches 256 points. In the vast majority of cases, the test level of the stand-alone version of the machine is specified at more than 1000 points, which is far from meeting the actual needs of the multi-entity model specifications, sizes and test levels.

Using the system to export 3D process electronic product wire harness processing and assembly video animation, can provide good professional services for electrical product assembly workers, the actual effect of gait analysis is remarkable, further reduce the wire harness processing and installation accuracy, improve the wire harness processing and installation production efficiency.

Telephone:+86 0512-55258242 Cell phone:+86 18916656629 website:seedwords.cn Add: No.6 Building, East side, No.77 Shunyang Road, Huaqiao Town, Kunshan City, Jiangsu Province